Direct Source Factory · OEM/ODM Services · Worldwide Shipping

Transparency is key to trust. Explore our 6-step manufacturing process that ensures every Yideli product meets global standards.

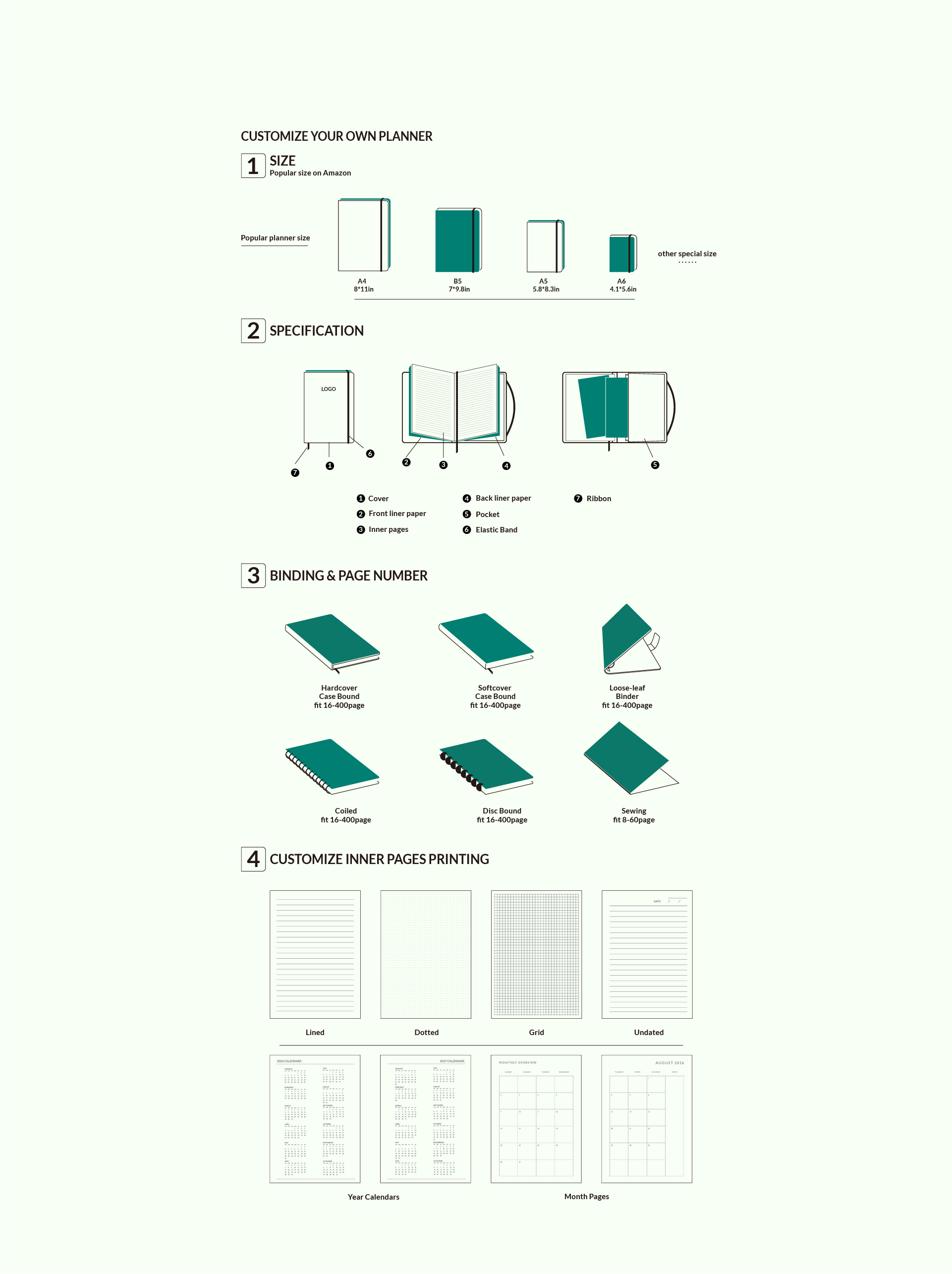

It all starts with an idea. Our in-house design team collaborates with global trend forecasters to create ergonomic and aesthetically pleasing designs. We use 3D modeling and rapid prototyping to test form and function before mass production begins.

Quality begins with raw materials. We source premium ABS/PP plastics, eco-friendly wheat straw composites, and high-grade papers (FSC certified) from trusted suppliers. Incoming materials undergo strict inspections for durability and safety (EN71-3).

Our workshop is equipped with 50+ automated injection molding machines. For notebooks, we utilize Heidelberg offset printing presses to ensure vibrant cover colors and crisp inner lines. Logo customization is handled via silk-screen, pad printing, or laser engraving.

Components are assembled using a mix of automated robotic arms and skilled manual labor. For pens, ink refills are inserted and tested for flow. For notebooks, binding (glue, spiral, or stitching) is performed with high precision machinery to ensure longevity.

Every batch undergoes AQL 2.5/4.0 inspection standards. We conduct writing distance tests, drop tests, and high-temperature storage tests. Only products that pass 100% of our checkpoints proceed to packaging.

Quality Management

Social Compliance

Sustainable Paper

European Safety Standard

We welcome international clients to visit our factory in Taizhou. Schedule a tour to witness our production capacity and quality control firsthand.

Book a Factory Tour